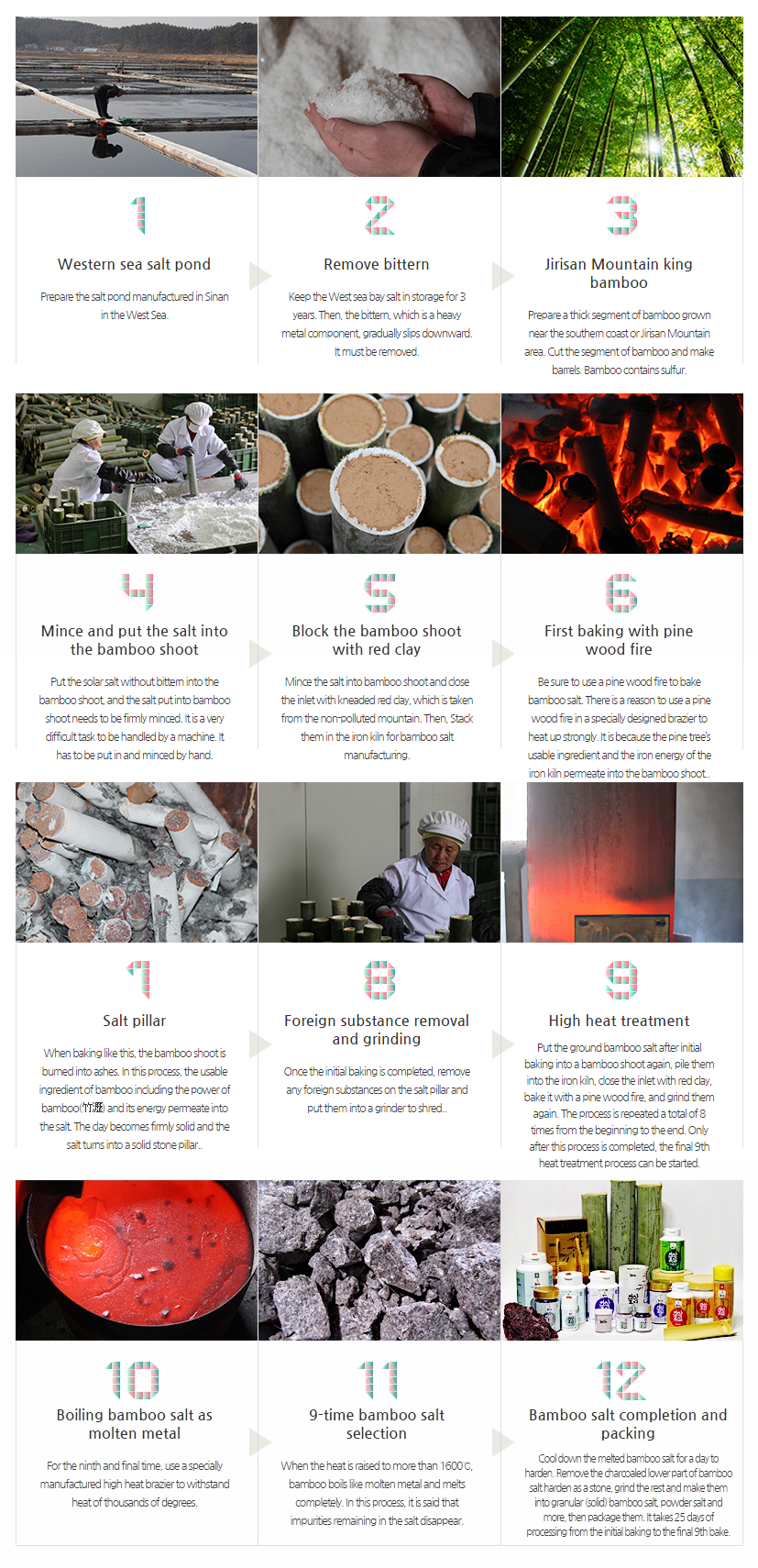

Manufacturing process of bamboo salt

Bamboo salt, and high reducing power.

Reducing power is the force that reduces the oxidized material back to its original state.

Bamboo salt, and high reducing power.

Reducing power is the force that reduces the oxidized material back to its original state.

Prepare the salt pond manufactured in Sinan in the West Sea.

Keep the West sea bay salt in storage for 3 years. Then, the bittern, which is a heavy metal component, gradually slips downward. It must be removed.

Prepare a thick segment of bamboo grown near the southern coast or Jirisan Mountain area. Cut the segment of bamboo and make barrels. Bamboo contains sulfur.

Put the solar salt without bittern into the bamboo shoot, and the salt put into bamboo shoot needs to be firmly minced. It is a very difficult task to be handled by a machine. It has to be put in and minced by hand.

Mince the salt into bamboo shoot and close the inlet with kneaded red clay, which is taken from the non-polluted mountain. Then, Stack them in the iron kiln for bamboo salt manufacturing.

Be sure to use a pine wood fire to bake bamboo salt. There is a reason to use a pine wood fire in a specially designed brazier to heat up strongly. It is because the pine tree’s usable ingredient and the iron energy of the iron kiln permeate into the bamboo shoot..

When baking like this, the bamboo shoot is burned into ashes. In this process, the usable ingredient of bamboo including the power of bamboo(竹瀝) and its energy permeate into the salt. The clay becomes firmly solid and the salt turns into a solid stone pillar..

Once the initial baking is completed, remove any foreign substances on the salt pillar and put them into a grinder to shred..

Put the ground bamboo salt after initial baking into a bamboo shoot again, pile them into the iron kiln, close the inlet with red clay, bake it with a pine wood fire, and grind them again. The process is repeated a total of 8 times from the beginning to the end. Only after this process is completed, the final 9th heat treatment process can be started.

For the ninth and final time, use a specially manufactured high heat brazier to withstand heat of thousands of degrees.

When the heat is raised to more than 1600℃, bamboo boils like molten metal and melts completely. In this process, it is said that impurities remaining in the salt disappear.

Cool down the melted bamboo salt for a day to harden. Remove the charcoaled lower part of bamboo salt harden as a stone, grind the rest and make them into granular (solid) bamboo salt, powder salt and more, then package them. It takes 25 days of processing from the initial baking to the final 9th bake.